Gerber to CAD Translations,Gerber-to-CAD reverse engineering tool,Tebo CAM, Tebo-Ict Test Fixture Software, HP3070, Agilent3070,i5000,i1000,Keysight i3070,i5000,i1000,Agilent Test Coverage Consultant,TestSight Developer, Test Expert( Fabmaster),VayoPro-Test-Expert,VayoPro-SMT-Expert

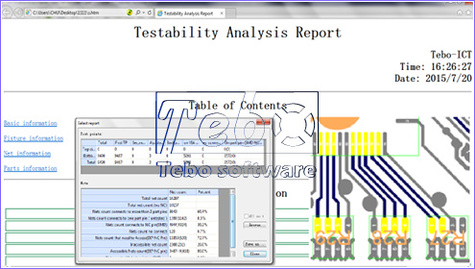

Tebo TA V6.0 ( DFT Design for testability of software) Is unique within the electronics industry also has CAD Gerber Input connector professional / Fast Design for Testability analysis software. Can quickly and accurately with Gerber restored to CAD data, maximize its use of design CAD data with the material BOM data Through intelligent integration testing process and fixture manufacturers production requirements ; Design for Testability DFT(Design For Testability) , Designed to provide accurate test points Layout And effective cost control software. Before you can create a detailed understanding of the network, parts test coverage information and probe the size and distribution of information, rather than after.

So that the product can not only keep for a few days DFT Analysis, down to a few minutes of work, but also fast generate a detailed data report. Can not only shorten new product introduction and reduce the cost of test fixture, and you avoid the new product design information ( DFT External cooperation) to meet data security The need for confidentiality .

Software Systems using open & Human design. WINDOWS COM technology structure, high reliability, easy to upgrade and maintain. Compatible with Win 2000/NT/XP/7/8/10 system, easy operation and training easier.

■ Fixture manufacturers widely use Tebo software analysis data is not "On Paper"

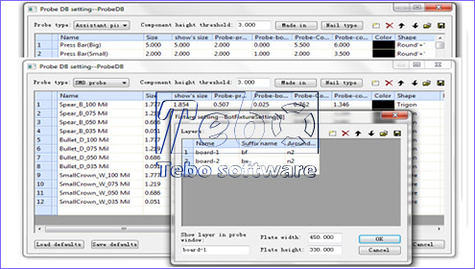

Input the fixture manufacturer directly (Probe DB) library. Genuine production fixture design verification test point at the request of rationality, Data analysis can be directly used for fixture production.

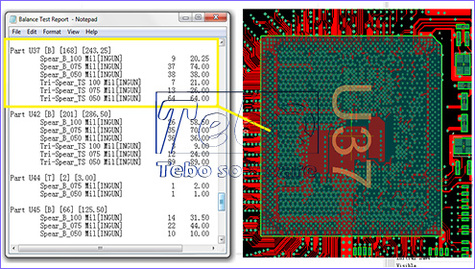

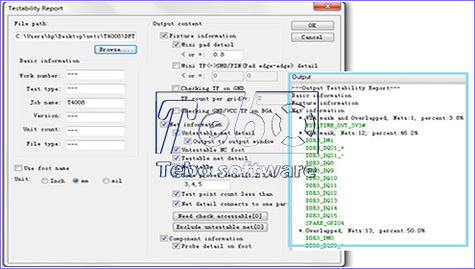

■ Can produce a detailed design for Testability Analysis reports

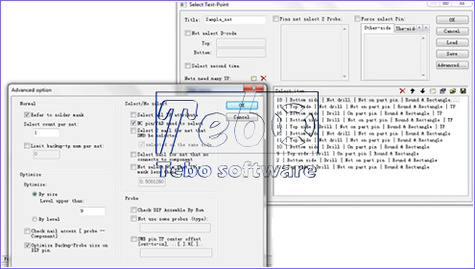

Rule analysis / Network testing / Parts coverage / Probe the size and distribution of the information report / Not needle causes can be classified, sort notes, designed to provide accurate test points Layout. Statistical evaluation of governance costs, unpredictable network print as a PDF file to the design department and quality control departments.

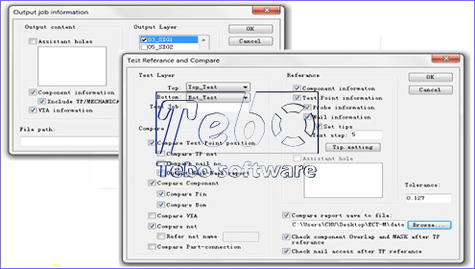

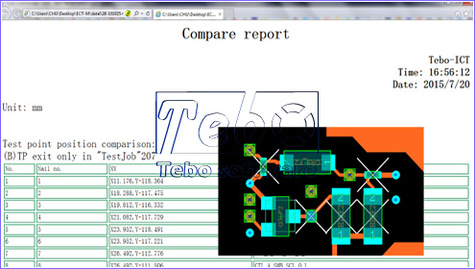

■ Gerber/CAD Version Compare & BOM Check function

Compare different versions of Gerber&CAD The data source , Difference report output components / Network diversity report. Printed and marked difference images , Check the rod support hole for collision , To maximize shared test fixture and fixture cost savings.

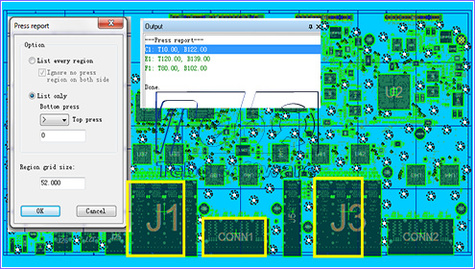

■ Output element (BGA/IC) probe report and the back press bar space report

Reports probe type / The number of / Elastic condition for RD Reference , Avoid measuring point design PCB Distribution, which centers on the plate, resulting in IC Chip elastic at the bottom too big / damage. Check the component layout is reasonable, whether it is because PCBA test does not have space for the press bar, and PCBA deformation.